Zero Defects?

“Zero defects” sounds good until you operationalize the definition of a defect.

Zero defects fails when the goal-post thinking associated with specification limits is used. Quality declines when process variation is not addressed. Costs increase as inspection, scrap and rework occurs. Key sources of customer satisfaction—repeatability and reliability—are not produced when tighter tolerances, rather than variation reduction, is the focus. Downstream problems increase as tolerance stack-up produces poor fitting parts and frustrating process hand-offs. Many specifications do not address variation in the interactions between processes and parts.

Terms used as an equivalent to the phrase “Specification limits” exist in abundance across all industries. You will recognize many of these words and phrases:

System Requirements, Hardware Specifications, Performance Criteria

Customer Service Specifications, Merchandising Standards

Accommodation Requirements, ADA Compliance, Individualized Plan for Employment (IPE), Case Management Standards

Building Codes, Blueprints, Design Specifications

Regulatory Compliance Requirements, Financial Reporting Standards, Investment Criteria, Risk Tolerance Levels

Curriculum Standards, Accreditation Requirements, Learning Objectives

Crop Specifications, Livestock Health Standards, Organic Certification Requirements, GMO Guidelines, Soil Quality Standards

Emissions Standards, Safety Standards, Fuel Efficiency Standards, Crash Test Criteria

Patient Care Standards, Medical Equipment Specifications, Electronic Health Record (EHR) Standards, HIPAA Compliance, Clinical Practice Guidelines

Product Quality Standards, ISO Standards, Production Capacity Requirements, Process Control Specifications, Materials Specifications

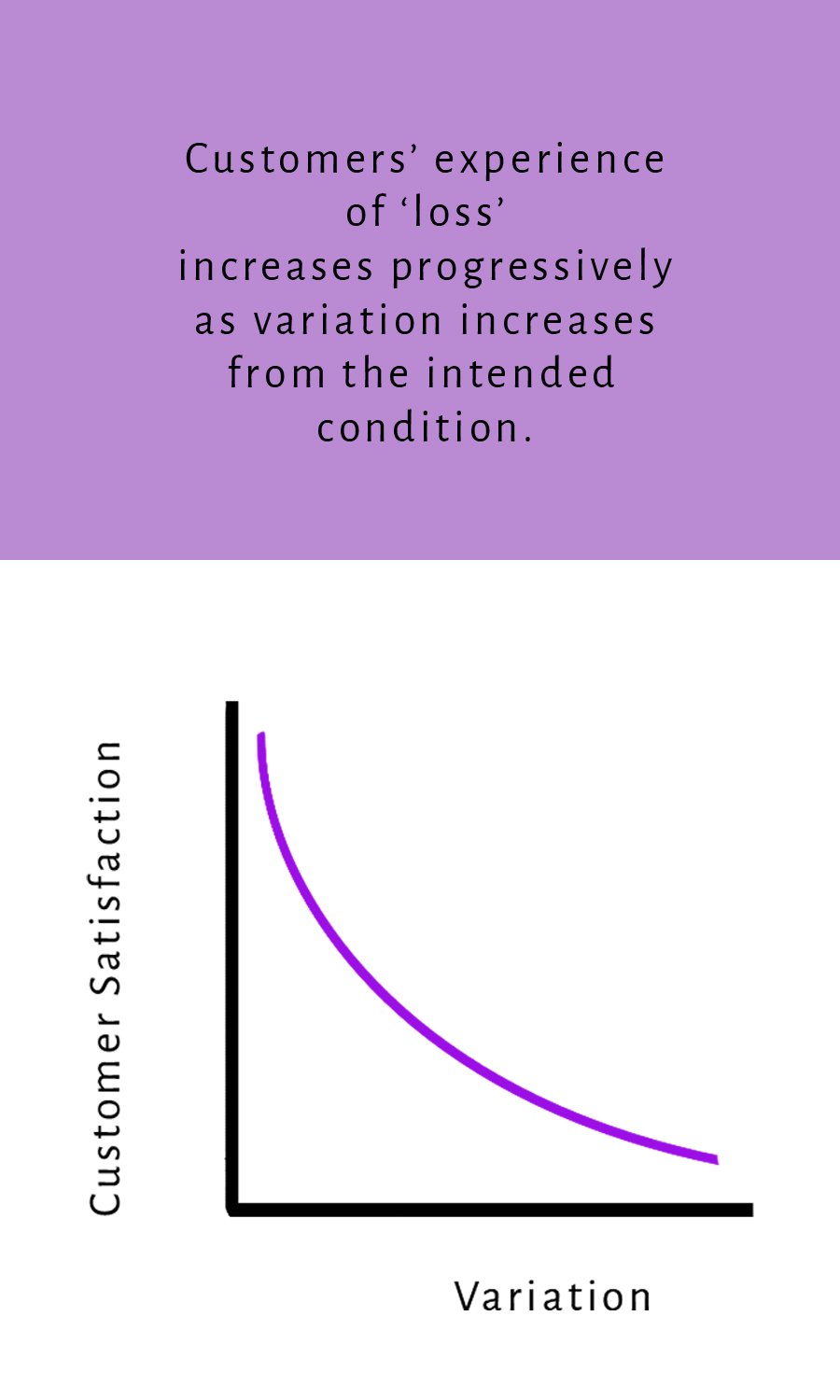

David Langford tells us that Dr., Deming always referred to Dr. Genichi Taguchi and the Taguchi’s Loss Function as one of the best, the greatest breakthroughs in systems. The Loss Function highlights the loss to society that occurs as process outputs vary from a client defined nominal value. Langford showed us how to apply the Taguchi Loss Function to solve daily problems in education and business (see “Tool Time for Education: Loss Function” ver. 15.0, page 72-73).

The visual results of Langford’s exercise applying the Taguchi Loss Function are impactful and valuable for decision making in groups. By identifying and choosing the least amount of loss, the exercise also integrates Prospect Theory from Kahneman and Tversky.